- Individual parts / small series / medium series

- Workstations, flexibly designed, on 2,000 m²

- Welding processes: MAG / MIG / WIG

- Black – White – Separation

- on request: 3D – Measuring and Documentation

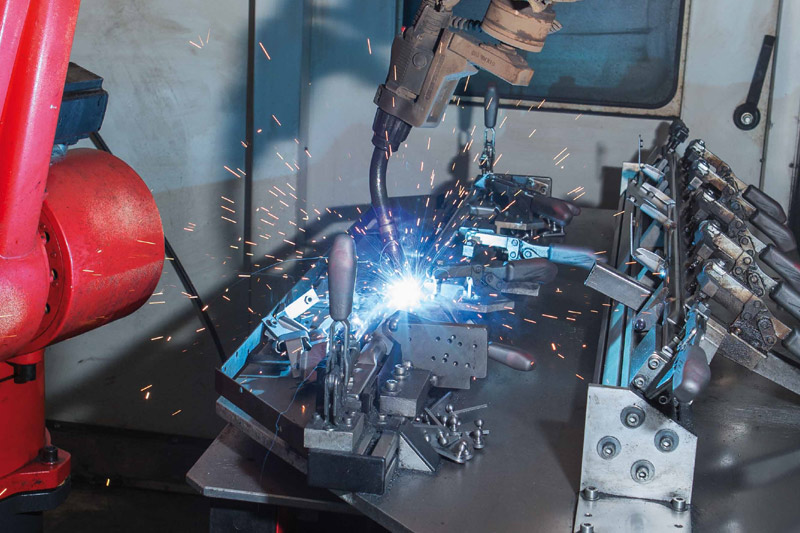

Welding (robots)

- Industrial robot compact cells, max. dimensions: 1,200 x 500 x 500 mm (L/W/H) with CMT power source and stud welding technology

- Cobot with multi-station operation and manipulator; 2,000 x 1,000 x 1,000 mm (L/W/H)

- Double gantry system with 2 suspended 6-axis robots; max. dimensions: 7,000 x 2500 x 2500 mm (L/W/H)

- Laser welding max. dimensions: 3.000 x 1.500 x 1.500 mm (L/B/H)

- on request: 3D – Measuring and Documentation

Assembly

- flexible assembly workstations on an area of 2000 m²

- flexible parts design and shortest delivery times thanks to in-house sheet metal production and chipping

- Assembly of simple components through to complex machines (max. 5,000 kg)

- Screws, presses, rivets, …

- Doubling of the assembly area possible at short notice

- 3D measurement and documentation on request

- “just-in-time” delivery